Our technical staff have been specially trained in the restoration and servicing of the TD 124 by the former Head of Development of Thorens Audio Division. The Schopper restoration, including our replacement motor bearing, restores the turntable to its original performance specifications and even results in some significant improvements - all of which build on the original's specific design philosophy and strengths.

The TD-124 offers unparalleled musical performance. From the point of view of technical specifications, the TD 124 can compete with any modern turntable, but it is above all the Thorens' unmatched ability to convey the heart and soul of music through vinyl reproduction which has established its reputation. As Art Dudley noted in his recent Listener column devoted to the restoration of the TD124, the turntable is a masterpiece of precision engineering in the service of music. Every mechanical and electronic component was designed, engineered and manufactured for a specific purpose - Thorens never used off-the-shelf parts. However, with time - the earliest TD 124 is now nearly 70 years old! - even the best-made parts degrade and deteriorate. Realizing the potential of the TD 124 requires a full restoration.

The fundamental problem of the TD 124 was (and remains) the motor - a problem which is, incidentally, common to all other turntables using the E 50 motor. The motor, which was not produced by Thorens but sourced from suppliers, inevitably suffered from technical limitations, namely the quality of the bearing. Cost considerations - at the beginning of the 60's an E 50-type motor cost some 10 euros to manufacture - meant that the motor quality is simply no match for the other elements which define the astonishing overall quality of the TD 124. The original motor bearings were made from tinned bronze. After 40 years, these have become dried and brittle. No simple oiling can solve the problem

Now, after many years of research and experimentation, we can offer a bearing for the E 50 motor which has been designed without cost compromise, to tolerances of 1/1000 mm. We install the bearing and replace all worn parts, after which the motor is run in for two weeks. The motor is then opened once more to remove any loose filings, after which it is precisely calibrated. The motor is replaced in the chassis and run for an additional week under real-world conditions, after which all chassis elements are finely adjusted. The motor restoration results in the following:

- At 33 RPM proper speed is reached after only one platter rotation

- Speed stability remains absolutely constant

- Measurably lower noise and vibration

- Years of troubel-free turntable use.

The TD 124 is said to "rumble". However, this rumble is not produced by the idler wheel drive mechanism, but where present results from vibrations caused by vibrating, poorly-mounted motors. Our TD 124 service results in measurable performance equal to that of a modern high-end turntable.

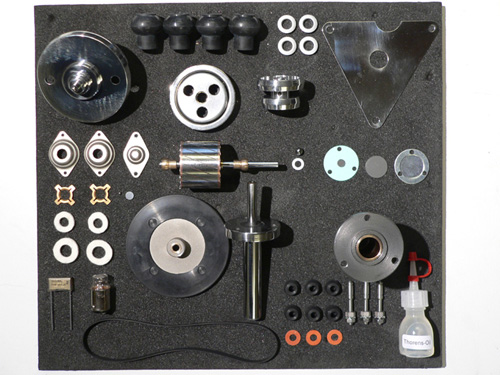

Our chassis and motor restoration includes the following parts and services:

- Full motor restoration.

- MK I models will be automatically converted into MK II motor mounting with our Kit # 3003

- Replacement of the motor suspension damping system with our Motor-Damping-Set FD 81 for optimal decoupling of the motor from the chassis.

- Complete chassis restoration. The chassis is completely disassembled and cleaned of all oil and grease. All parts, fixed and moving, are replaced as necessary, and the chassis is greased and oiled according to original factory specifications, after which the restored motor is reinstalled.

- Full restoration of the main platter bearing, including our kit # 3002

- Step Pulley refurbishing and replacement of the bottom plate.

- New belt manufactured to our strict specifications.

- Refurbishing of the main AC switch and replacement of the switch compressor condenser

- The strobe lamp strobe is replaced.

- Exchange of the Thorens Sticker

- Extensive endourance run under listening condition

Even if your Thorens runs well, the complete chassis/motor restoration will improve performance dramatically, with a reduction of noise/rumble up to 15 db!

Noise spectrum Analysis before and after the restoration: Analysis 1 and Analysis 2

Price for Motor and chassis Restoration: CHF 990.--

Additional we install a high quality shielded power cord with the plug of your desire, 1.5 m lenght, for CHF 90.--

The restoration does not include shipping cost, replacing the idler wheel or mushrooms, repainting the chassis, nor does it include replacing missing parts.

PLEASE NOTE:

We cannot repair replacement Papst motors.

The chassis must be complete! - we can not replace missing parts. Only complete chassis will be accepted for service.

We are frequently asked if the idler wheel is routinely replaced as part of the service. This is only rarely necessary - in 90% of all cases the idler wheel can be successfully restored. However, for customers desiring a new idler wheel, a replacement unit can be supplied and will be separately billed.

Procedure

If you decide to send us your TD 124 for the motor and chassis restoration, please contact us before and we will give you the shipping instruction.

After we received your TD 124, we will check it carefully and will contact you with a statement of the condition and if there are any missing parts. We also will let you know, if there will be any additional works and replacements necessary which are not included in the basic fully chassis and motor restoration. For example:

- Step Pulley restoration for Emporium, earliest MK I series

- Restoration of early Main Platter Bearing with plastic bushings and for all other TD 124 which have used or defect bushings

After we receive your confirmation, we will start with the restoration. Including the endourance run, it will takes about 4 - 6 weeks. We will contact you again with the bill, when your TD 124 is ready for sending back to you. Payment is requested at this time. For payment we accept Paypal, credit cards or transfer to our bank account.

The Five steps to the perfect TD 124

1. Full restoration

2. Non magnetic platter

3. New plinth

4. New Armboard

Contact us for your restoration request by e-mail

unrestored E 50 motor:

restored E 50 motor with polished motor pulley:

DE

DE  EN

EN