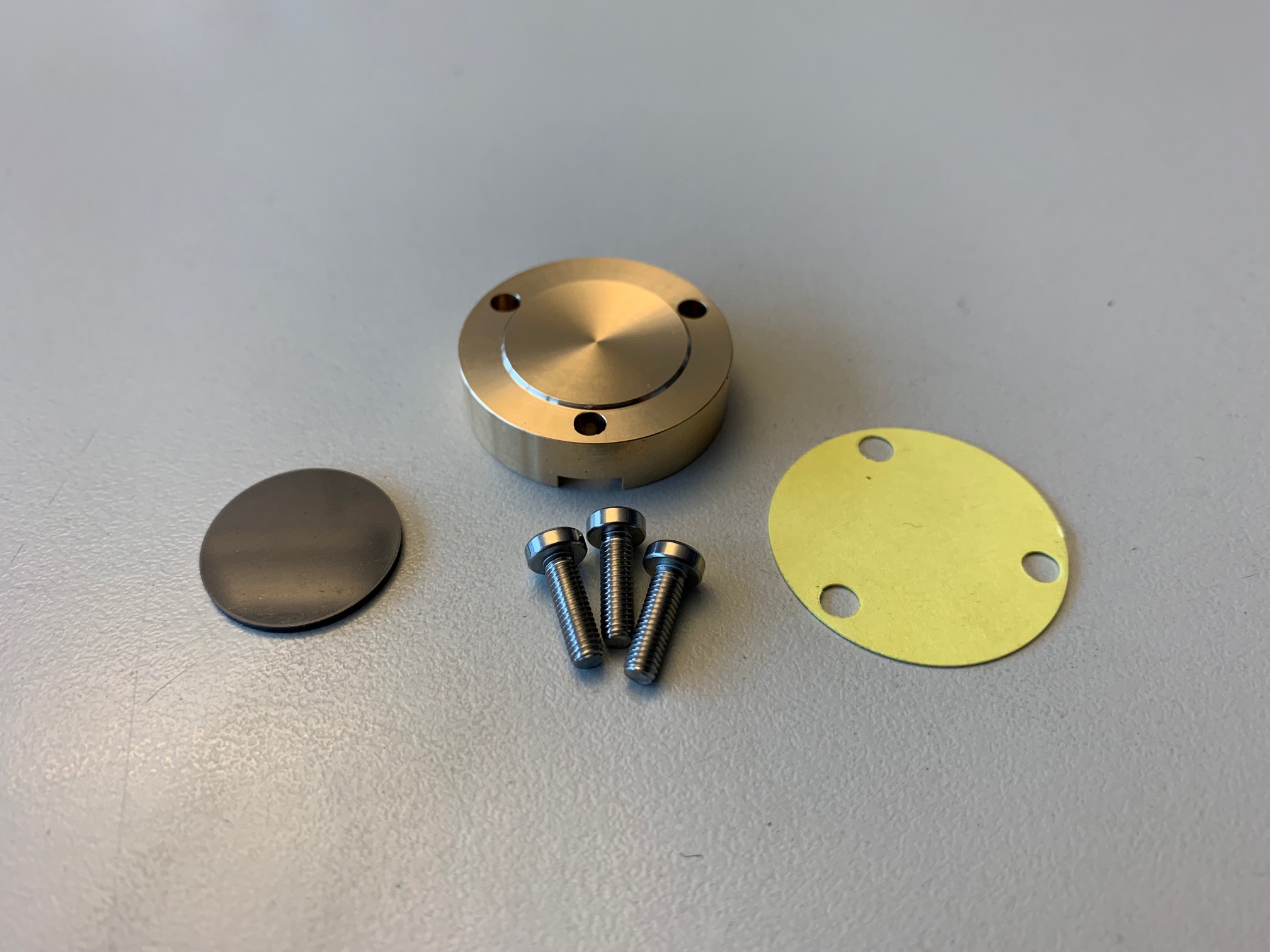

New available:Thrust bearing plate made from bronze for the main platter bearing of the TD 124.

100% Swissmade

A repair kit is available for the TD 124 main platter bearing. After decades of use, even with professional handling, some degree of excess play invariably affects the bearing tolerances, degrading overall performance.

The TD 124 series motor suspension dampers were made of rubber and become brittle and dry over the years. For optimal decoupling of the motor from the chassis these suspension rod dampers must be replaced, otherwise motor vibration will be transmitted through the chassis to the armboard and into the arm and cartridge.

Correct decoupling of the motor from the chassis is a key element in any turntable design. Poor decoupling produces rumble and speed/pitch variations. This was recognized early on by Thorens, and accounts for the differences in motor decoupling between the TD 124 Mark I and Mark II models.

With the neon strobe lamp illuminating the stroboscopic markings on the underside of the main platter rotational speed can be accurately and repeatedly set to tolerances of +/- 3%.

Replacing the switch suppressor condensor is an indispensable part of servicing/restoring the TD 124 series turntables.

Over time, the originals lose their lustre and become difficult to turn on their support screws, making it impossible to achieve precise leveling of the turntable. Unlike the originals, our leveling wheels are anodized and will preserve their attractive finish.

DE

DE  EN

EN

Often, the Strobe Mirror is scratched, broken or blind.

Often, the Strobe Mirror is scratched, broken or blind.